In an era where sustainability is more critical than ever, industries are increasingly focusing on recycling to minimize environmental impact and conserve resources. One area that has gained significant attention is scrap metal recycling for manufacturers in Massachusetts. Recycling plays a pivotal role in sustainable manufacturing and industrial practices by reducing waste, conserving natural resources, and lowering greenhouse gas emissions. In this blog, we’ll explore how manufacturers in Massachusetts can integrate scrap metal recycling into their operations to achieve these sustainability goals.

The Importance of Recycling in Manufacturing

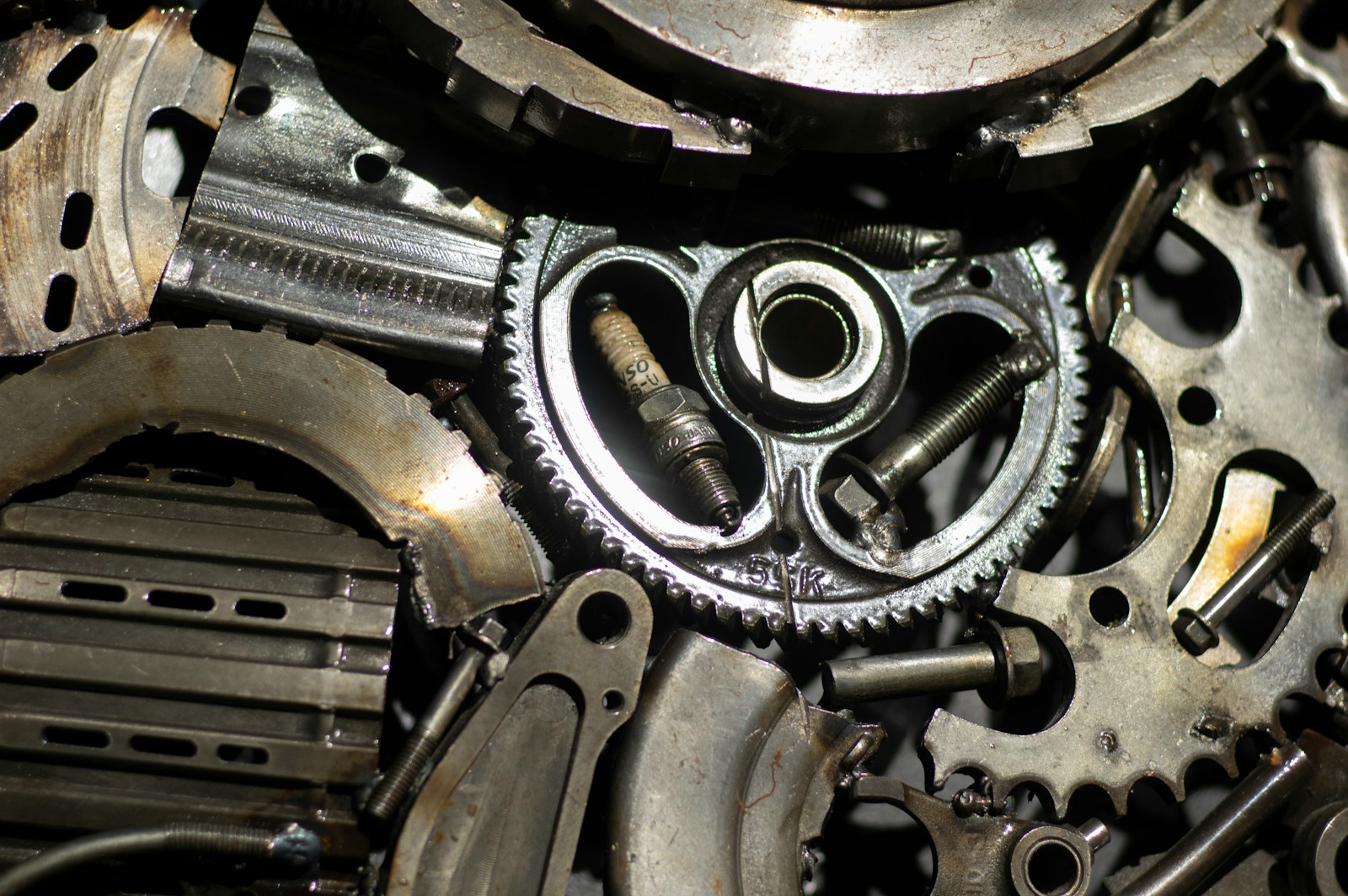

Manufacturing processes often generate considerable amounts of scrap metal, whether it’s from production line excess, discarded machinery, or byproducts of the manufacturing process. Traditionally, this scrap metal might have ended up in landfills, contributing to environmental degradation. However, with the rising awareness of sustainability, recycling has become an essential practice in the manufacturing sector.

Benefits of Scrap Metal Recycling for Manufacturers

Conservation of Natural Resources

One of the most significant benefits of recycling scrap metal is the conservation of natural resources. Every time metal is recycled, the need for mining new raw materials is reduced. This not only preserves natural landscapes but also conserves the finite resources from which metals are extracted. For manufacturers in Massachusetts, adopting scrap metal recycling can help in reducing the raw material costs and contribute to resource conservation efforts.

Energy Savings

Recycling scrap metal uses significantly less energy compared to the energy required to mine and process new metal from ore. For instance, recycling aluminum saves up to 95% of the energy needed to produce new aluminum from raw materials. This energy efficiency translates to cost savings for manufacturers. By incorporating scrap metal recycling into their practices, manufacturers in Massachusetts can reduce their energy consumption and operational costs.

Reduction in Greenhouse Gas Emissions

Manufacturing processes, particularly those involving metal production, are typically energy-intensive and contribute to greenhouse gas emissions. Recycling scrap metal helps to lower these emissions by reducing the need for energy-intensive metal production processes. Sustainable practices like these can assist manufacturers in Massachusetts in meeting regulatory requirements and corporate sustainability goals.

Financial Benefits

Scrap metal recycling is not just good for the environment; it also offers substantial financial benefits. Recyclable metals have intrinsic value; thus, by selling scrap metal, manufacturers can generate additional revenue. Additionally, the reduced need for raw materials and energy can lead to significant cost savings. These financial benefits make recycling an attractive proposition for manufacturers in Massachusetts.

Integrating Recycling into Manufacturing Practices

Conduct a Waste Audit

The first step for manufacturers looking to integrate scrap metal recycling is to conduct a waste audit. This involves analyzing the types and quantities of scrap metal generated in the manufacturing process. By understanding their waste streams, manufacturers can develop targeted recycling strategies and identify opportunities for waste reduction.

Partner with a Reliable Recycling Facility

Choosing a reliable recycling facility is crucial for effective scrap metal recycling. Excel Recycling is a leading provider of scrap metal recycling services for manufacturers in Massachusetts, offering competitive rates and comprehensive recycling solutions. Partnering with a trusted recycler ensures that your scrap metal is processed responsibly and efficiently.

Establish Internal Recycling Programs

Manufacturers should establish internal recycling programs to streamline the collection and processing of scrap metal. This includes setting up designated recycling bins, training employees, and implementing procedures for sorting and storing scrap metal. By fostering a culture of recycling within the organization, manufacturers in Massachusetts can enhance their sustainability efforts.

Implement Tracking and Reporting Systems

Tracking and reporting the quantities of recycled scrap metal can provide valuable insights into the effectiveness of recycling programs. Implementing a tracking system allows manufacturers to monitor their progress, identify areas for improvement, and report on their sustainability achievements. These metrics can serve as key performance indicators for corporate sustainability goals.

The Role of Excel Recycling

Excel Recycling specializes in scrap metal recycling for manufacturers in Massachusetts, providing tailored solutions to meet the unique needs of the manufacturing industry. Our services include:

– Efficient Scrap Metal Collection: We provide convenient collection solutions to ensure minimal disruption to your manufacturing processes.

– Competitive Rates: Our extensive network enables us to offer competitive prices for your scrap metal, maximizing your returns.

– Sustainable Practices: We adhere to strict environmental standards, ensuring that your scrap metal is recycled responsibly.

Conclusion

Recycling plays a fundamental role in sustainable manufacturing and industrial practices. For manufacturers in Massachusetts, integrating scrap metal recycling into their operations can lead to significant environmental and financial benefits. By partnering with Excel Recycling and implementing robust recycling programs, manufacturers can contribute to a more sustainable future while improving their bottom line. Contact Excel Recycling today to learn more about our scrap metal recycling services and how we can support your sustainability goals.